what is bending test|four point bending test equipment : mail order Bend testing is the most commonly, economical and simple qualitative mechanical testing used to check the material ductility and soundness. The test is more commonly applied as a QC tool to butt/ groove .

Resultado da This is a GitHub repository that provides an M3U playlist for free TV channels around the World. You can use it to point your IPTV player to .

{plog:ftitle_list}

web5 de fev. de 2024 · Alles Spitze Auszahlungsquote/ RTP und Volatilität. Je nachdem, welche Strategie angewandt wird, liegt der Alles Spitze RTP bei 91,57% bis 98,67%. Die .

A bending test (bending tensile test) is a method of testing materials for their bending strength and other important properties. Destructive materials testing is used for plastics, fiber-reinforced plastics (FRP), metals and ceramic materials. Bending test is used to determine the tensile strength of brittle materials that are generally difficult to test in uniaxial tension due to cracking in the grips. The most .

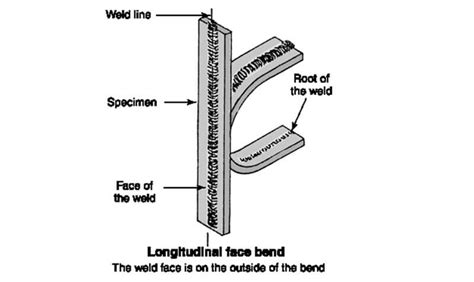

transverse vs longitudinal bend test

The bend test is a simple and inexpensive qualitative test that can be used to evaluate both the ductility and soundness of a material. It is often used as a quality control test for butt-welded joints, having the advantage of simplicity of .

Bend Testing 101. How much or how little a material will bend can determine its suitability for use in a product or structure. A bend test measures flexural strength, strain or stress to find out whether that material is a good choice for . Flexural testing, or bend testing, is a key part of basic materials characterization. This video discusses the equipment used when performing a bend test and . Bend testing is the most commonly, economical and simple qualitative mechanical testing used to check the material ductility and soundness. The test is more commonly applied as a QC tool to butt/ groove .

A bend test, also known as the flexural test, is a standardized method employed to assess the ductility, bend strength, fracture strength, and resistance to fracture of materials. This testing methodology involves subjecting a specimen to a .The Bend Test: How to Do It. In order to perform a bend test, a sample is put into a bend test machine with a bend fixture in such a way that the midpoint of the sample is bent to form a concave surface with a specific radius of curvature. Flexural testing, or bend testing, is a key part of basic materials characterization. This video discusses the equipment used when performing a bend test and.The guided bend test deforms the sample weld into a “U” shape, putting tensile stress on the outside surface and compressive stress on the inner surface. If the weld stays together and doesn’t crack, it’s good enough to be welded. What Is .

Test setup. In the bending flexural test, a specimen is loaded under uniaxial bending stress (tension and compression) in order to obtain information on the bending behaviour of materials.Especially brittle materials .A bend test, also known as the flexural test, is a standardized method employed to assess the ductility, bend strength, fracture strength, and resistance to fracture of materials.This testing methodology involves subjecting a specimen to a controlled bending force to evaluate its resistance to deformation. The bend test is important in construction processes involving .

1.1 These test methods cover bend testing for ductility of materials. Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force the mid-length of the specimen between two supports separated by a defined space; a semi-guided bend test in which the .A bend test measures flexural strength, strain or stress to find out whether that material is a good choice for the intended end use. While bend tests are often conducted on metals, plastics and other materials, this type of measurement is especially important when evaluating today’s newly developed composite materials.Flexural testing, or bend testing, is a key part of basic materials characterization. This video discusses the equipment used when performing a bend test and explains why this testing is important. Learn more about bend testing. Learn more about flexure fixtures.The three standard bending strength tests are the cantilever beam bend test, the three-point bend test, and the four-point bend test. European Standard EN 12384 specifies a bend test to determine the modulus of elasticity in bending. Japanese Industrial Standard JIS 3130 specifies two tests to determine the elastic limit of spring plate or .

Another test utilized in the investigation of fracture in concrete specimens is the four-point bending test (4pbt), whose setup can be seen in Fig. 2.8 which is very similar to the 3pbt beams, except that two halved forces (F/2) are applied at a certain distance on both sides of the notch, rather than being directly applied to the notch at the .In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, .

Results from bend testing are typically reported as the smallest R/T (the ratio between the die radius and the sheet thickness) that results in a crack-free bend. Many steel companies report minimum bend test limits for various grades and certain automakers include minimum bend test requirements in their specifications as well.

The beam bending test is a test that is conducted by applying a force on a test specimen to bend the material. When conducting a bending test the material can either be simply supported or cantilevered. Regardless of how the test specimen is supported the bending test is used to determine how different materials react when subject to bending .The Bending Test Materials testing is a fundamental part of Materials Science and Engineering, in understanding the limits of materials through determining their physical and mechanical properties. The information collected during laboratory experimentations are useful to engineers and researchers in helping to The Adam’s forward bend test is a simple and non-invasive screening exam that can effectively detect the presence of indicators for scoliosis. This is highly advantageous as there are numerous benefits to early detection in terms of treatment efficacy. These types of screening tests are invaluable as they can lead to a diagnosis that might .

The welding bend test is a popular mechanical testing method for determining the ductility and strength of welded connections. A welded specimen is subjected to bending forces to determine its capacity to sustain deformation without fracture or failure. We provide a full explanation of the welding bend test in this post, including the machine .A 10-year follow-up evaluation about the effectiveness of school screening for scoliosis shows that Adam’s forward bend test has a sensitivity of 84.3%, a specificity of 93.44% for a cobb angle >10° but the authors of the study .

guided bend test machine

Test results include flexural strength and flexural modulus. Brittle Materials. When a 3-point bend test is done on a brittle material like ceramic or concrete, flexural strength is often called modulus of rupture (MOR). This test provides flex .The bending strength of each test piece is calculated by determining the ratio of the bending moment M, at the maximum load F max, to the moment of its full cross-section. For a simply supported beam with central loading, deflection under the load is given by :

Bending tests are conducted by placing a length of material across a span and pushing down along the span to bend the material until failure. Bending tests reveal the elastic modulus of bending, flexural stress, and flexural strain of a material. 3-Point bending involves placing the material across a span supported on either ends of the material and bringing down a point . What is Bending Stress? Bending stress is a pivotal concept in solid mechanics and structural analysis. Every structure, from towering skyscrapers to the smallest mechanical components, consists of various parts that contribute to the structure’s ability to bear loads and resist deformation.

The t-bending test has been accustomed to evaluate the formability of distinct coating systems in a cooperative way. The T-bend test results are registered in the form 'xT' where the x denotes the . Three-Point flexural Test. In a three-point bending strength test, a continually increasing load is applied at the center of the sample till there is a breakage or permanent bend in the material. A flexural test machine can apply increasing amounts of force and precisely record the amount of force at the point of breaking.

It’s a simple test that involves having a patient stand and bend over at a 90-degree angle. Advantages of a Forward Bending Test. A forward bending test is a simple, noninvasive test used to evaluate a patient’s spine. The test is a go-to for medical professionals conducting an exam on a patient who’s concerned they might have scoliosis.Flexural strength: The maximum bending stress that the test specimen can sustain before it yields. Flexural strength measurements are expressed in force per unit area. Flexural offset yield strength: The stress at which the stress-strain curve deviates by a given strain (offset) from the tangent to the initial straight line portion of the curve . To perform the test, the patient stands upright while the examiner observes from behind for any obvious curvature . 7 The patient is then asked to bend forward to bring the spine parallel with the . Detech.co.id – Pengertian Uji tekuk (bending test) merupakan salah satu bentuk pengujian untuk menentukan mutu suatu material secara visual. Proses pembebanan menggunakan mandrel atau pendorong yang dimensinya telah ditentukan untuk memaksa bagian tengah bahan uji atau spesimen tertekuk diantara dua penyangga yang dipisahkan oleh jarak .

four point bending test equipment

custom general pinless moisture meter readings wme

It tests the ability of unreinforced concrete beam or slab to withstand failure in bending. The results of flexural test on concrete expressed as a modulus of rupture which denotes as (MR) in MPa or psi. The flexural test on concrete can be conducted using either three point load test (ASTM C78) or center point load test (ASTM C293).

custom general pinless moisture meter reviews

custom general pinless non marring moisture meter

WEB4 dias atrás · David Dee Delgado for The New York Times. The 93-year-old widow of a Wall Street financier has donated $1 billion to a Bronx medical school, the Albert Einstein .

what is bending test|four point bending test equipment